However, where these materials are used as electrical insulation, such materials should be tested in accordance with Test Methods D229 and Test Method 651.

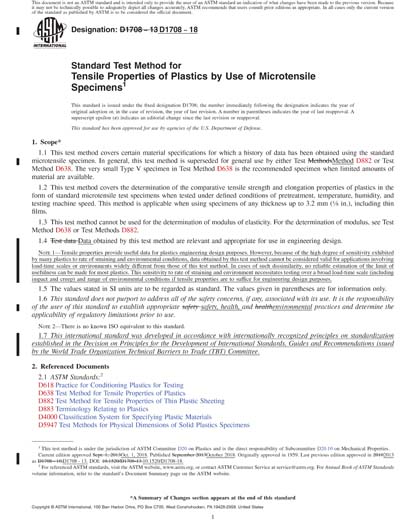

Note 3-This test method may be used for testing phenolic molded resin or laminated materials. Special additional tests should be used where more precise physical data are needed. Hence, where directly comparable results are desired, all samples should be of equal thickness. Further, it is realized that variations in the thicknesses of test specimens, which are permitted by these procedures, produce variations in the surface-volume ratios of such specimens, and that these variations may influence the test results. It is recognized that the constant rate of crosshead movement type of test leaves much to be desired from a theoretical standpoint, that wide differences may exist between rate of crosshead movement and rate of strain between gage marks on the specimen, and that the testing speeds specified disguise important effects characteristic of materials in the plastic state. Note 2-This test method is not intended to cover precise physical procedures. Note 1-This test method and ISO 527-1 are technically equivalent. Materials with a thickness greater than 14 mm (0.55 in.) must be reduced by machining.ġ.3 This test method includes the option of determining Poisson's ratio at room temperature. However, for testing specimens in the form of thin sheeting, including film less than 1.0 mm (0.04 in.) in thickness, Test Methods D882 is the preferred test method. 1.1 This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed.ġ.2 This test method can be used for testing materials of any thickness up to 14 mm (0.55 in.).

0 kommentar(er)

0 kommentar(er)